PROCESS OPTIMIZATION

Building a Smarter Supply

Order System for Stokes

With over 100 stores across Canada submitting orders by email, the Stokes marketing team was stuck manually transferring requests into spreadsheets — a slow, error-prone process that made tracking and fulfillment tedious.

I set up and launched an automated order intake system using Microsoft Forms to streamline submissions, cut manual work, and improve accuracy.

Overview

Role

Service & Workflow Designer

Tools

Microsoft Forms

Outcome

-

Saved Time

Reduced order time per store and eliminated manual entry, saving hours of admin work each week.

-

Improved Accuracy

Standardized item details to eliminate manual entry errors and reduce missing items in store orders.

-

Enabled Insights

Enabled a clear record of orders to help plan for supply delays and avoid unexpected stockouts.

The existing process involved store associates emailing their orders to a shared marketing inbox. From there, a team member would manually input each item into a spreadsheet until fulfillment day. The spreadsheet was hard to follow, time-consuming to update, and prone to human error.

Major pain points included:

Stores often requested unavailable signage due to lack of clear information.

Inconsistent item descriptions caused back-and-forth clarifications.

Manual data entry errors led to incomplete shipments.

The shared inbox was constantly flooded with emails.

Orders included items for other departments, adding confusion.

No reliable record of outgoing supplies made inventory planning difficult.

Store network restrictions ruled out external tools.

Understanding the problem

Objective

Design an automated, reliable order system that solved key operational pain points within existing technical constraints. The new system needed to:

Standardize the marketing supply catalog across all stores

Eliminate manual data entry and formatting

Simplify fulfillment with an auto-generated, easy-to-read spreadsheet

Provide visibility into order volume for basic inventory tracking

Be accessible on store iPads and simple for non-technical team members

Allow the marketing team to update content in-house, with no advanced technical skills

Operate entirely within Microsoft 365

Process

The first step was to understand the technical and operational constraints. I worked with IT to confirm what tools were accessible at the store level: each location had an iPad with limited Safari access but full Microsoft 365 support, so the solution needed to run entirely within that ecosystem.

Next, I clarified the marketing team’s needs. Simplicity was critical — the system had to be easy for anyone on the team to maintain without technical expertise.

I then audited the full marketing supply catalog, identified all available signage and assets, and organized them into clear categories to inform a user-friendly form structure.

After reviewing the Microsoft 365 options, I chose Forms because it automatically generated structured data and was the easiest tool for non-technical marketing team members to update themselves. This ensured stores could submit orders easily, and the marketing team could manage the system without needing IT support.

Solution

Using Forms, I built a structured ordering system that let stores submit requests directly, without relying on email or manual entry. Marketing supplies were standardized and categorized in a single form, making it easy for stores to place accurate orders and eliminating invalid or inconsistent entries.

The form automatically generated a clean, fulfillment-ready spreadsheet — simplifying prep and reducing errors. It also standardized quantities for certain supplies, like price slashers, which stores had previously ordered in varying amounts. With a fixed count per order, the team could pre-divide these items in advance, saving time during fulfillment.

Submissions were tracked automatically, giving the marketing team visibility into order volume and trends, including potential over-ordering — insight they didn’t have before. And because orders went through Forms, the shared marketing inbox was no longer flooded, significantly reducing daily noise.

To support all stores across Canada, I provided French and English versions of the form, created home screen icons for quick access on store iPads, and developed clear, step-by-step documentation.

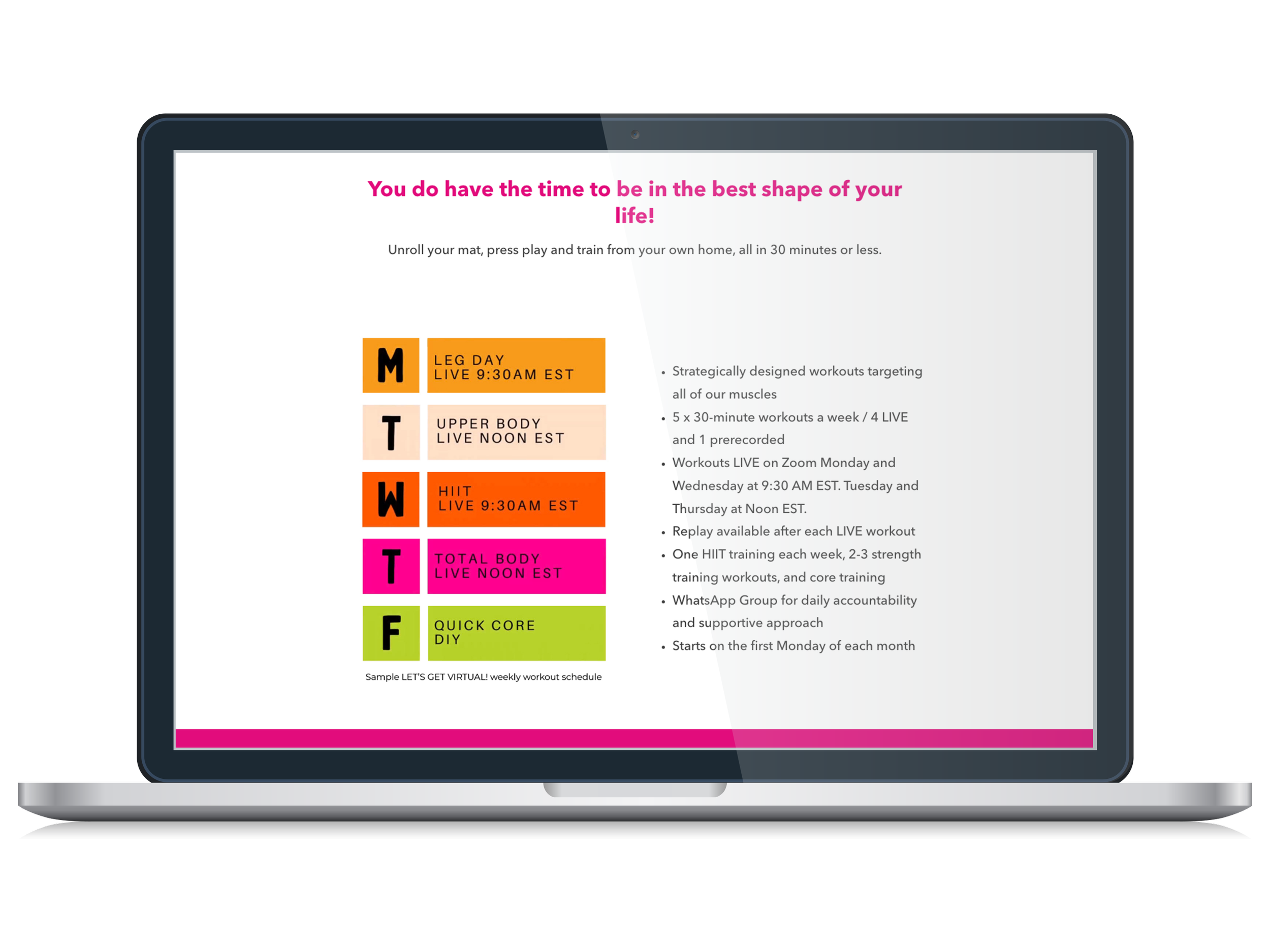

A section of the Microsoft Form used by store associates to submit marketing supply orders — categorized for quick navigation, limited to available items only, and supplemented with images where applicable.

The custom icons created for the home screen provided quick access to the English and French versions of the form.

A glimpse of the user guide available through the intranet — designed to help associates troubleshoot basic issues without additional support.

Before rolling out the system to all stores, I tested the form with associates from 25 randomly selected locations. I also created a separate feedback form to gather comments and technical accessibility notes.

The response was overwhelmingly positive. Associates liked the clear catalog and how easy it was to place orders. The main feedback was about navigation: while the form was already divided into categories and pages, some users found it time-consuming to click through each page if they only needed one section.

To address this, I added a landing screen with direct links to each category, so associates could jump straight to the section they needed. I also added a notes field at the end of the form to capture any extra requests.

Validating the form

User Feedback

Next Steps

A valuable next step would be to expand the order form into a full internal ordering portal — a single place where stores can request supplies from any department without needing to know who to contact.

A few simple tools, structured well, can solve big operational headaches without costly overhead.

More Case Studies